*Executive Summary: For beauty brand owners and procurement specialists, understanding the intricate journey of custom glass bottle creation is more than technical knowledge—it’s strategic advantage. This 2,000-word guide deconstructs the entire process from concept to delivery, revealing how premium packaging transforms from raw materials to brand-defining assets. We explore not just the “how” but the “why” behind each manufacturing decision, providing actionable insights for your next packaging investment.*

Introduction: Why Glass Packaging Demands Your Strategic Attention

In an increasingly saturated beauty market where 76% of consumers base purchasing decisions on packaging quality (McKinsey, 2024), glass containers represent more than mere vessels—they embody brand philosophy, environmental commitment, and sensory experience. Unlike mass-produced alternatives, custom glass bottles offer 47% higher perceived value according to consumer studies, translating directly to premium pricing power and market differentiation.

This definitive guide serves beauty procurement professionals and brand founders seeking to navigate the complex yet rewarding territory of custom glass manufacturing. Beyond procedural knowledge, we illuminate the critical decision points that impact cost, timeline, and final quality—empowering you to collaborate effectively with manufacturers and maximize your packaging investment.

Section 1: Strategic Design & Engineering Foundations

1.1 The Collaborative Blueprinting Phase

The journey begins where aesthetics meet engineering. Successful custom glass bottles emerge from synergistic collaboration between your creative vision and manufacturing reality. This phase determines 60% of the final project’s success while influencing only 15% of total costs—making it the highest-return investment in your packaging development.

Critical Activities:

- 3D Concept Translation: Your sketches or references transform into precise digital models using CAD software, allowing virtual stress testing and ergonomic evaluation.

- Design for Manufacturing Analysis: Experienced engineers assess wall thickness consistency, stress distribution, and molding feasibility, proposing optimizations that maintain design intent while ensuring structural integrity.

- Prototyping Pathways: Depending on timeline and budget, brands select from:

- 3D printed resin models (72-hour turnaround, ±0.3mm accuracy)

- CNC-machined aluminum prototypes (2-week delivery, production-grade accuracy)

- Limited glass sample runs using temporary tooling

1.2 The Mold Engineering Ecosystem

Molds represent the single most significant capital investment in glass manufacturing, with costs ranging from $8,000 to $50,000+ depending on complexity. Understanding mold types enables smarter budget allocation:

| Mold Type | Investment Range | Ideal Production Volume | Lead Time | Key Advantage |

|---|---|---|---|---|

| Modular/Unit Molds | $8,000 – $15,000 | 50,000 – 200,000 units | 4-6 weeks | Cost-effective for medium batches |

| Dedicated Production Molds | $25,000 – $50,000 | 200,000 – 1M+ units | 8-12 weeks | Superior surface finish, faster cycle times |

| Multi-Cavity Systems | $40,000 – $80,000 | 500,000+ units annually | 10-14 weeks | Dramatically reduced per-unit cost at scale |

Table 1: Strategic Mold Investment Matrix for Beauty Brands

Technical Considerations:

- Mold Material Selection: Cast iron molds offer durability for high-volume runs, while alloy steels provide finer detail resolution for intricate embossing.

- Venting & Cooling Architecture: Hidden engineering elements that dramatically impact production speed and defect rates.

- Future-Proofing: Modular designs allowing for later addition of embossing or minor dimensional adjustments without complete retooling.

Section 2: The Alchemy of Glass Formation

2.1 Raw Material Science & Sustainability Integration

Modern glass formulations balance aesthetics, functionality, and environmental responsibility. The standard composition includes:

- Silica Sand (72%): Provides structural backbone; premium sources ensure clarity and purity

- Soda Ash (16%): Lowers melting temperature, reducing energy consumption

- Limestone (10%): Enhances chemical durability against cosmetic formulations

- Cullet (25-40%): Post-consumer recycled glass; higher percentages reduce carbon footprint

Advanced Material Innovations:

- UV-Filtering Glass: Incorporating cerium oxide for photosensitive formulations (vitamin C, retinoids)

- Lightweighting Technologies: Advanced coatings maintaining strength while reducing weight by up to 30%

- Coloration Systems: Precise Pantone matching through metallic oxide additives (cobalt for blue, chromium for green)

2.2 Precision Forming Methodologies

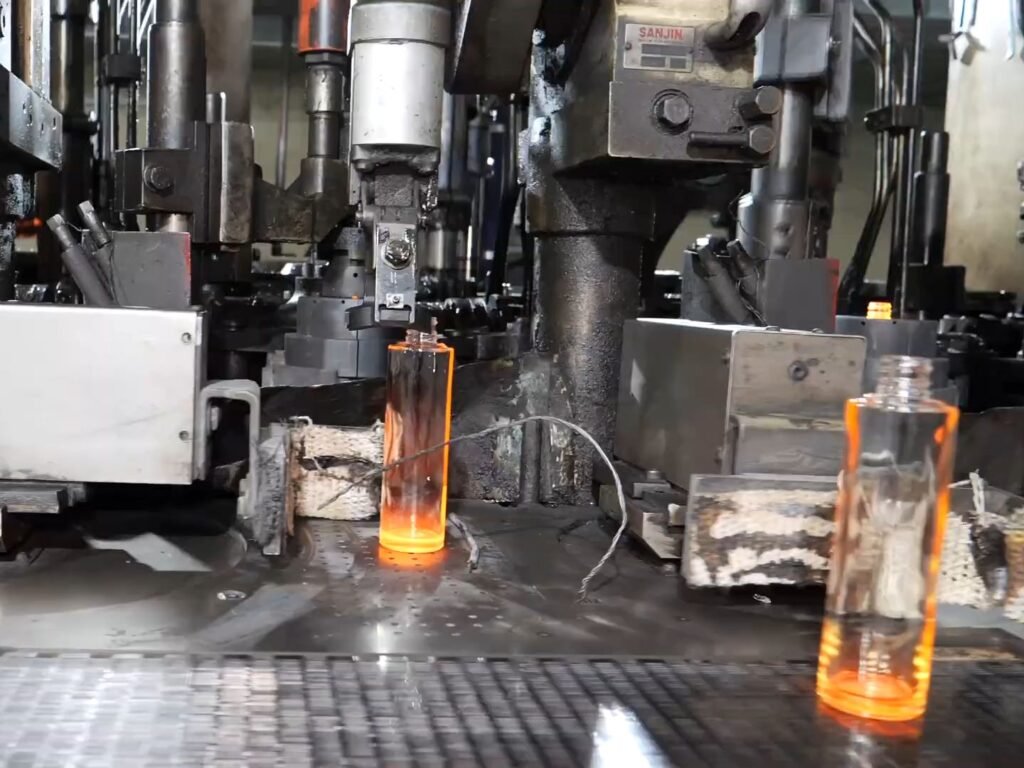

The transformation from 1,500°C molten glass to precise containers occurs through two primary methods, each with distinct brand implications:

A. Blow-and-Blow Process

Ideal for: Elegant, thin-walled bottles (perfumes, serums)

- Molten glass enters preliminary mold, receives initial “parison” shape

- Transferred to final mold, compressed air expands glass to mold contours

- Brand Advantage: Creates seamless, flowing contours with superior optical clarity

B. Press-and-Blow Process

Ideal for: Sturdy containers with precise dimensions (jars, thick-walled bottles)

- Gob of molten glass pressed into shape by metal plunger

- Subsequent blowing completes formation

- Brand Advantage: Exceptional dimensional accuracy (±0.25mm), ideal for automated filling lines

2.3 The Critical Annealing Process

Often overlooked but crucial, annealing removes thermal stresses through controlled cooling in lehr ovens:

| Temperature Zone | Duration | Purpose | Quality Impact if Compromised |

|---|---|---|---|

| Stress Relief | 575°C → 450°C (2-4 hours) | Allows glass molecules to reorganize | Bottles susceptible to thermal shock breakage |

| Slow Cooling | 450°C → 350°C (3-5 hours) | Prevents new stress formation | Increased fragility during handling |

| Rapid Cooling | 350°C → 50°C (1-2 hours) | Final stabilization | Surface defects (checking) may appear later |

Table 2: Annealing Parameters and Quality Implications

Section 3: Customization & Value-Added Finishing

3.1 Surface Enhancement Technologies

Post-formation treatments transform standard glass into branded masterpieces:

Frosting & Texturing Methods:

- Acid Etching: Creates uniform satin finish; ideal for luxurious feel but requires environmental controls

- Sandblasting: Offers variable texture depths; perfect for logo highlighting or grip enhancement

- Ceramic Coating: Applied then fired at 600°C; provides permanent color or texture without altering recyclability

Decorative Application Matrix:

| Technique | Minimum Order | Lead Time | Durability | Cost Factor | Best For |

|---|---|---|---|---|---|

| Screen Printing | 5,000 units | 2-3 weeks | Excellent | $$ | Multi-color designs, brand storytelling |

| Heat Transfer | 3,000 units | 3-4 weeks | Good | $$$ | Photographic quality, complex gradients |

| Embossing | 10,000 units | 6-8 weeks* | Permanent | $$$$ | Luxury positioning, tactile engagement |

| UV Digital Printing | 500 units | 1-2 weeks | Good | $$$$ | Prototypes, limited editions, personalization |

*Includes mold modification time

Table 3: Decorative Technique Selection Guide

3.2 Precision Closure Integration

The interface between bottle and closure represents a critical failure point if not engineered properly. Advanced solutions include:

- Laser-Measured Thread Profiling: Ensuring perfect cap alignment and seal integrity

- Anti-Backoff Thread Designs: Preventing product tampering and leakage during shipping

- Dual-Seal Systems: Combining traditional threading with inner silicone seals for volatile formulations

Section 4: The Uncompromising Quality Regimen

4.1 Multi-Stage Inspection Protocol

Reputable manufacturers implement inspection at four critical checkpoints:

Checkpoint 1: Dimensional Validation

- Automated vision systems verify 15+ critical dimensions against CAD specifications

- Tolerance Standards: Critical dimensions ±0.4mm, non-critical ±0.8mm

- Statistical Process Control tracking identifies production drift before exceeding limits

Checkpoint 2: Structural Integrity Testing

- Internal Pressure Testing: Up to 6 bar for aerosol or carbonated products

- Thermal Shock Assessment: Moving from 0°C to 50°C water baths repeatedly

- Impact Resistance: Standardized drop tests from 1.2 meters onto steel plates

Checkpoint 3: Cosmetic Perfection Screening

- Human inspectors under calibrated lighting examine for:

- Seeds (tiny bubbles): Acceptable if <0.3mm and not in viewing area

- Stones (unmelted particles): Zero tolerance

- Cord (streaking): Acceptable only if consistent and not affecting clarity

Checkpoint 4: Compatibility Validation

- Fill simulations with actual product formulations

- 45-day stability testing under accelerated conditions

- Closure torque consistency across 1,000+ open/close cycles

4.2 Certifications & Compliance Framework

| Standard | Scope | Testing Frequency | Documentation Provided |

|---|---|---|---|

| FDA CFR 21 | Material safety, heavy metals | Each batch | Certificate of Compliance |

| EU 10/2011 | Food contact materials | Annual | Declaration of Conformity |

| ISO 9001:2015 | Quality management systems | Continuous | Audit reports available |

| ASTM C162 | Glass terminology & standards | As needed | Test reports |

Table 4: Essential Regulatory Compliance for Global Distribution

Section 5: Strategic Procurement Considerations

5.1 Total Cost of Ownership Analysis

Forward-thinking procurement professionals evaluate beyond unit price:

Comprehensive Cost Components:

- Tooling Investment: Amortized across projected volumes

- Per-Unit Manufacturing Cost: Varies by complexity (typically $0.85 – $3.50)

- Secondary Processing: Decoration, special packaging

- Logistics & Duties: Weight-based shipping, import tariffs

- Risk Mitigation: Quality failures, supply chain disruptions

Hidden Value Opportunities:

- Lightweighting Savings: Every 100g reduction saves approximately $0.12 in shipping per unit internationally

- Standardization Benefits: Using existing mold bases for future designs reduces tooling costs by 30-40%

- Regional Manufacturing: Producing closer to fill locations reduces carbon footprint and transit damage risk

5.2 Sustainability Metrics That Matter

Beyond recyclability, progressive brands track:

- Carbon Intensity: Typically 0.5-0.8 kg CO2 per 100ml glass bottle

- Cullet Utilization Rate: Leading manufacturers achieve 40%+ recycled content without quality compromise

- Closed-Loop Potential: Take-back programs creating circular systems

- Water Usage Efficiency: Advanced plants recycle 95%+ of process water

Conclusion: Transforming Packaging from Cost Center to Brand Asset

The creation of custom glass cosmetic bottles represents a sophisticated intersection of art, science, and commerce. For discerning beauty brands, this process offers unparalleled opportunities to:

- Differentiate Viscerally through tactile, sensory experiences that digital marketing cannot replicate

- Communicate Values Authentically via material choices and manufacturing transparency

- Build Operational Resilience through supplier partnerships based on technical collaboration

- Future-Proof Investments via designs that accommodate evolving regulatory and consumer landscapes

The most successful brands approach glass packaging not as a procurement exercise but as brand architecture—where every dimensional decision, material selection, and finishing detail consciously reinforces market positioning and consumer connection.

Strategic Next Steps for Procurement Teams:

- Internal Alignment Workshop: Bring together marketing, product development, and sustainability teams to establish packaging objectives before supplier engagement

- Technical Capability Assessment: Develop a weighted scorecard evaluating potential partners on engineering support, innovation history, and quality systems

- Phased Development Plan: Begin with achievable complexity, building technical partnership confidence before advancing to more ambitious designs

- Lifecycle Cost Modeling: Project 3-year total packaging costs including tooling amortization, logistics, and potential redesign savings

The transition from standardized containers to custom glass solutions represents a measurable competitive advancement. In an industry where packaging influences 52% of repeat purchase decisions (Forbes, 2024), mastering these manufacturing fundamentals transforms packaging from a necessary expense into a measurable brand accelerator.