Introduction: The Strategic Value of Custom Glass Dropper Bottles

Glass dropper bottles have evolved from simple containers to strategic brand assets in the cosmetic, skincare, pharmaceutical, and essential oil industries. For international procurement professionals, understanding the complete customization process—from initial concept to final delivery—is crucial for ensuring quality, managing costs, and maintaining supply chain efficiency. This comprehensive guide provides the essential knowledge needed to navigate the complexities of custom glass packaging procurement.

Phase 1: Design and Specification Development

This phase transforms creative concepts into technically executable packaging solutions.

1.1 Bottle Design Parameters

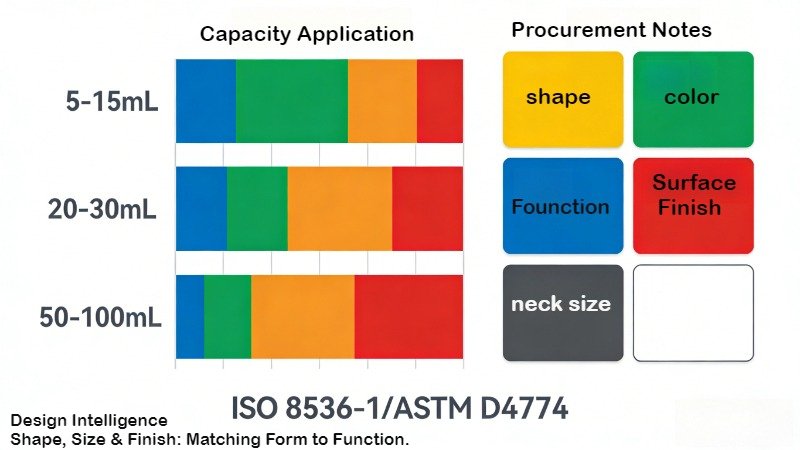

Capacity and Dimension Standards:

| Capacity Range | Common Applications | Industry Standards |

|---|---|---|

| 5-15 mL | Luxury serums, essential oil samples | ISO 8536-1 (medical) |

| 20-30 mL | Mainstream skincare, tinctures | ASTM D4774 (cosmetic) |

| 50-100 mL | Professional use, bulk oils | USP <661> (pharmaceutical) |

Design Options Comparison:

| Feature | Options | Procurement Considerations |

|---|---|---|

| Bottle Shape | Boston round, European flat, Apothecary square, Curved ergonomic | Tooling costs, filling line compatibility |

| Glass Color | Amber (UV protection), Cobalt blue, Clear (display), Custom tints | Light sensitivity requirements, MOQ implications |

| Surface Finish | Glossy, Frosted (acid-etched), Matte coating, Textured patterns | Additional processing time, cost premiums |

| Neck Finish | 18/410, 20/410, 22/410 standard sizes | Dropper assembly compatibility |

1.2 Dropper System Components

Component Specifications Table:

| Component | Material Options | Key Specifications |

|---|---|---|

| Glass Pipette | Soda-lime glass, Borosilicate (Type I) | Graduation markings (±5% accuracy), Tip orifice size (1.5-3.0 mm) |

| Bulb | Natural rubber, Silicone, EPDM | Durometer (20-40 Shore A), Chemical compatibility certification |

| Cap/Collar | PP, PE, Aluminum, Tin-plated steel | CR (child-resistant) mechanisms, Thread compatibility |

| Seals | PE foam, PTFE-faced silicone | FDA 21 CFR compliance, Extractables testing |

Phase 2: Material Science and Quality Compliance

Selection of appropriate materials ensures product integrity and regulatory compliance.

2.1 Glass Composition Analysis

Glass Type Comparison:

| Property | Type I Borosilicate | Type III Soda-Lime | Ultraviolet Glass |

|---|---|---|---|

| Chemical Resistance | Excellent (USP Class A) | Good (with treatment) | Varies by color |

| Thermal Shock Resistance | High (Δ120°C) | Moderate (Δ60°C) | Moderate |

| UV Protection | Variable | Amber (99% UV block) | Cobalt (95% UV block) |

| Cost Factor | 2.0-2.5× baseline | 1.0× (baseline) | 1.2-1.8× baseline |

| Primary Applications | Pharmaceuticals, Sensitive formulations | Cosmetics, Essential oils | Light-sensitive compounds |

2.2 Global Regulatory Landscape

Essential Compliance Framework:

- EU Regulations: REACH, Cosmetics Regulation (EC) No 1223/2009, EUPIA guidelines

- US Standards: FDA 21 CFR Parts 174-186, California Proposition 65, USP <661>

- International Guidelines: ISO 22716 (Cosmetics GMP), ICH Q1A(R2) stability testing

- Sustainability: EPR regulations, Recycled content requirements (30-50% post-consumer recycled glass)

Phase 3: Manufacturing Process Deep Dive

Understanding production methodologies enables informed supplier evaluation.

3.1 Glass Manufacturing Workflow

Raw Material Preparation → Batch Formulation → Melting (1500-1600°C) → Forming (IS Machine) → Annealing (550°C gradual cooling) → Surface Treatment → Quality Inspection → Packaging

Critical Process Control Points:

- Batch Consistency: Raw material purity verification (SiO₂ ≥ 72%, Fe₂O₃ ≤ 0.04%)

- Forming Process: Dimensional tolerance control (±0.5 mm on diameter, ±1.0 mm on height)

- Annealing Cycle: Stress reduction to ≤ 50 nm/cm optical retardation

- Surface Treatment: Internal coating for chemical resistance (SPM or sulfur treatment)

3.2 Quality Assurance Protocols

Inspection Criteria Matrix:

| Test Category | Method | Acceptance Criteria | Frequency |

|---|---|---|---|

| Dimensional | Optical comparator | ±0.3 mm from CAD | Every 2 hours |

| Visual Defects | Automated inspection | No stones, seeds, or blisters | 100% inspection |

| Wall Thickness | Ultrasonic testing | ≥ 0.8 mm, uniform distribution | Per ASTM C148 |

| Chemical Resistance | Autoclave testing | ≤ 0.1 mg/dm² weight loss | Daily batch testing |

| Dropper Function | Flow rate testing | 0.9-1.1 mL per 20 drops | Per ISO 8871 |

Phase 4: Supply Chain and Logistics Management

Effective procurement requires strategic supply chain planning.

4.1 Project Timeline Framework

Standard Lead Time Breakdown:

| Phase | Duration | Key Dependencies |

|---|---|---|

| Design & Tooling | 25-35 days | Approval cycles, complexity of design |

| Material Procurement | 15-25 days | Glass color availability, specialty components |

| Production | 30-45 days | Order quantity, seasonal demand factors |

| Quality Testing | 7-14 days | Compliance documentation requirements |

| Shipping & Customs | 15-40 days | Incoterms, destination country regulations |

4.2 Cost Structure Analysis

Typical Cost Distribution:

- Raw Materials: 35-45% (glass quality, colorants, dropper components)

- Manufacturing: 25-35% (energy, labor, tooling amortization)

- Quality Control: 10-15% (testing, documentation, compliance)

- Logistics: 10-20% (packaging, shipping, insurance, duties)

MOQ Considerations by Component:

| Component | Standard MOQ | Breakthrough Quantity |

|---|---|---|

| Custom Molded Bottles | 50,000-100,000 units | 200,000+ units (cost reduction 5-8%) |

| Custom Glass Color | 5,000+ kg batch | 5,000+ kg (economies of scale) |

| Printed/Painted Decorations | 2,000 units per design | 2,000+ units (setup cost dilution) |

Phase 5: Supplier Qualification and Partnership

Strategic supplier relationships ensure long-term packaging success.

5.1 Supplier Evaluation Checklist

Technical Capability Assessment:

- ISO 9001:2015 and ISO 15378 certification

- In-house mold design and manufacturing capability

- Complete vertical integration (glass production to assembly)

- R&D department for material innovation

- Stability testing facilities (ICH climate zones)

Commercial Assessment Criteria:

- Transparent cost breakdown structure

- Flexibility in order volume adjustments

- Multiple shipping point options (FOB, CIF, DDP)

- Intellectual property protection agreements

- Co-development project history

5.2 Risk Mitigation Strategies

Common Procurement Risks and Solutions:

| Risk Category | Potential Impact | Mitigation Strategy |

|---|---|---|

| Supply Chain Disruption | 4-8 week delays | Dual sourcing, safety stock agreements |

| Quality Consistency | Batch rejection (2-5%) | Regular factory audits, statistical process control |

| Regulatory Changes | Non-compliance penalties | Monthly regulatory updates, compliance guarantees |

| Cost Volatility | 10-25% price fluctuations | Price adjustment clauses, long-term contracts |

Emerging Trends for Strategic Procurement

Forward-looking considerations for competitive advantage:

- Sustainability Integration:

- Closed-loop glass recycling programs

- Lightweighting initiatives (15-20% weight reduction)

- Carbon-neutral production certifications

- Smart Packaging Convergence:

- NFC-enabled caps for authentication

- QR code integration for consumer engagement

- Temperature-sensitive indicators

- Customization Evolution:

- Digital printing for short-run customization

- 3D-printed prototype acceleration (5-7 day samples)

- Modular design systems for SKU optimization

Conclusion: Building a Strategic Packaging Partnership

Successful procurement of custom glass dropper bottles requires moving beyond transactional purchasing to strategic partnership. By understanding the complete process from technical design through global logistics, procurement professionals can:

- Enhance Value Engineering: Identify cost-saving opportunities without compromising quality

- Mitigate Supply Chain Risks: Develop resilient sourcing strategies

- Accelerate Time-to-Market: Streamline approval processes and production scheduling

- Ensure Regulatory Compliance: Navigate complex international standards

- Drive Innovation: Leverage supplier expertise for competitive differentiation

The most successful packaging initiatives emerge from collaborative relationships where suppliers function as technical partners rather than mere vendors. This approach transforms custom glass dropper bottles from simple containers into powerful brand assets that deliver measurable market advantage.